Metal seated ball valves are preferred in severe service conditions like abrasive, corrosive fluid applications in high temperatures and pressures. In several industries, fluids could be a mixture of different ingredients like abrasive or corrosive media. Appropriately selected seat and ball surfaces show great resistance against severe service conditions.

High Performance Ball Valve

Size Range

2" - 24"

Pressure Ratings

ANSI 150 - 2500

Bore

Full - Reduced Bore

End Connections

RF - RTJ - BW - NPT Threaded

Specifications

| Valve Size | 2″ — 24″ |

| Valve Type | Trunnion |

| Body Type | Bolted |

| Pressure Class | ANSI 150 / 300 / 600 / 900 / 1500 / 2500 |

| End Connection | RF / RTJ / BW / NPT Threaded |

| Bore | Full Bore / Reduced Bore |

| Operator | Lever / Gear / Actuator |

| Material | Carbon Steel / Stainless Steel / Duplex / Alloy Steel / Titanium |

| Operating Temperature | Low / Standard / High |

| Leakage Class | API 598 / ANSI FC70-2 / ISO 5208 |

| Design Standard | ASME B16.34 / API 6D / ISO 14313 / ISO 17292 |

| Face to Face Standard | ASME B16.10 |

| End Connection Standard | ASME B16.5 / ASME B16.25/ DIN EN 1092-1 |

| Test Standard | API 6D / API 598 / ISO 14313 |

| Fire Safe Standard | API 607 / ISO 10497 / API 6FA |

| Certification | EN 10204 3.1 — 3.2 / ISO 15848 Fugitive Emission / 2014-68-EU PED / SIL Capable / IP 67 (Gearbox) |

| Isolation Type | DBB / DIB-1 / DIB-2 |

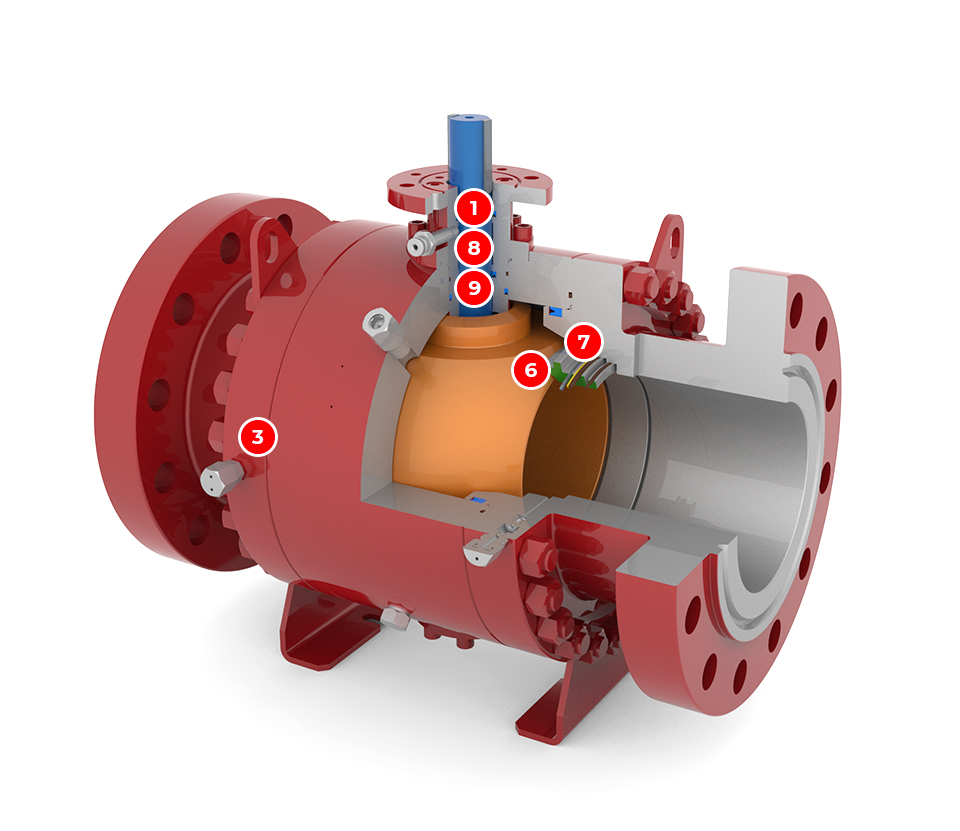

Features

| 1 | Due to low torque values, smaller actuator can be selected. |

| 2 | The actuator selection is automatic. |

| 3 | Fixed lifting lugs on the valve. |

| 4 | Easy maintenance. |

| 5 | Emergency sealing fittings can be added if needed. |

| 6 | Renewable seats. |

| 7 | Available with metal and soft seats. |

| 8 | Blow-out-proof stem. |

| 9 | Strengthened stem packing is optional. |

| 10 | Locking device is optional. |