Floating ball valves are generally used in instrumentation applications. It is often preferred in oil and gas industry due to its uniform and compact structure. It is often manufactured as forged and stainless steel material.

Instrumentation Ball Valve

Size Range

1/2" - 3"

Pressure Ratings

ANSI 150 - 1500

Bore

Full - Reduced Bore

End Connections

RF - RTJ - BW - SW - Threaded

Specifications

| Valve Size | 1/2″ — 3″ |

| Valve Type | Floating |

| Body Type | Screwed / Bolted |

| Pressure Class | ANSI 150 / 300 / 600 / 900 / 1500 |

| End Connection | RF / RTJ / BW / SW / Threaded |

| Bore | Full Bore / Reduced Bore |

| Operator | Lever / Actuator |

| Material | Carbon Steel / Stainless Steel / Duplex / Alloy Steel |

| Operating Temperature | Low / Standard / High |

| Leakage Class | API 598 / ANSI FC70-2 / ISO 5208 |

| Design Standard | ASME B16.34 / ISO 14313 / ISO 17292 |

| Face to Face Standard | ASME B16.10 / Acc. To Manufacturer Specs. |

| End Connection Standard | ASME B16.5 / ASME B16.25/ DIN EN 1092-1 |

| Test Standard | API 598 / ISO 14313 |

| Fire Safe Standard | API 607 / ISO 10497 / API 6FA |

| Certification | EN 10204 3.1 — 3.2 / ISO 15848 Fugitive Emission / 2014-68-EU PED |

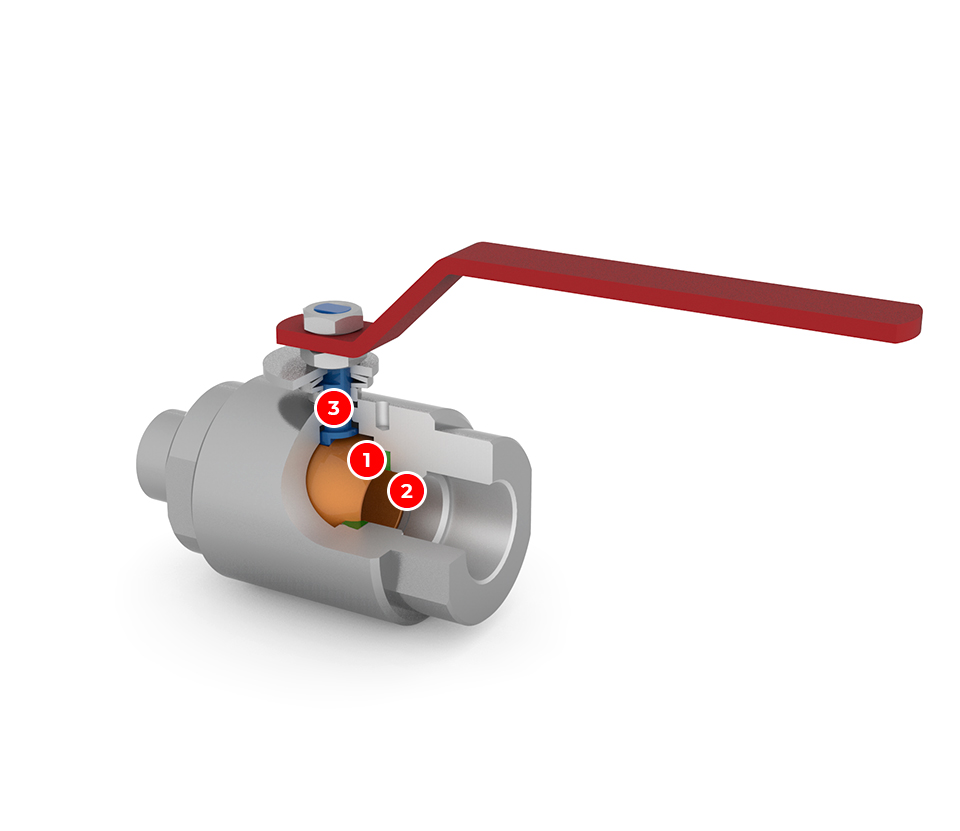

Features

| 1 | Renewable seats. |

| 2 | Available with metal and soft seats. |

| 3 | Blow-out-proof stem. |

| 4 | Locking device is optional. |