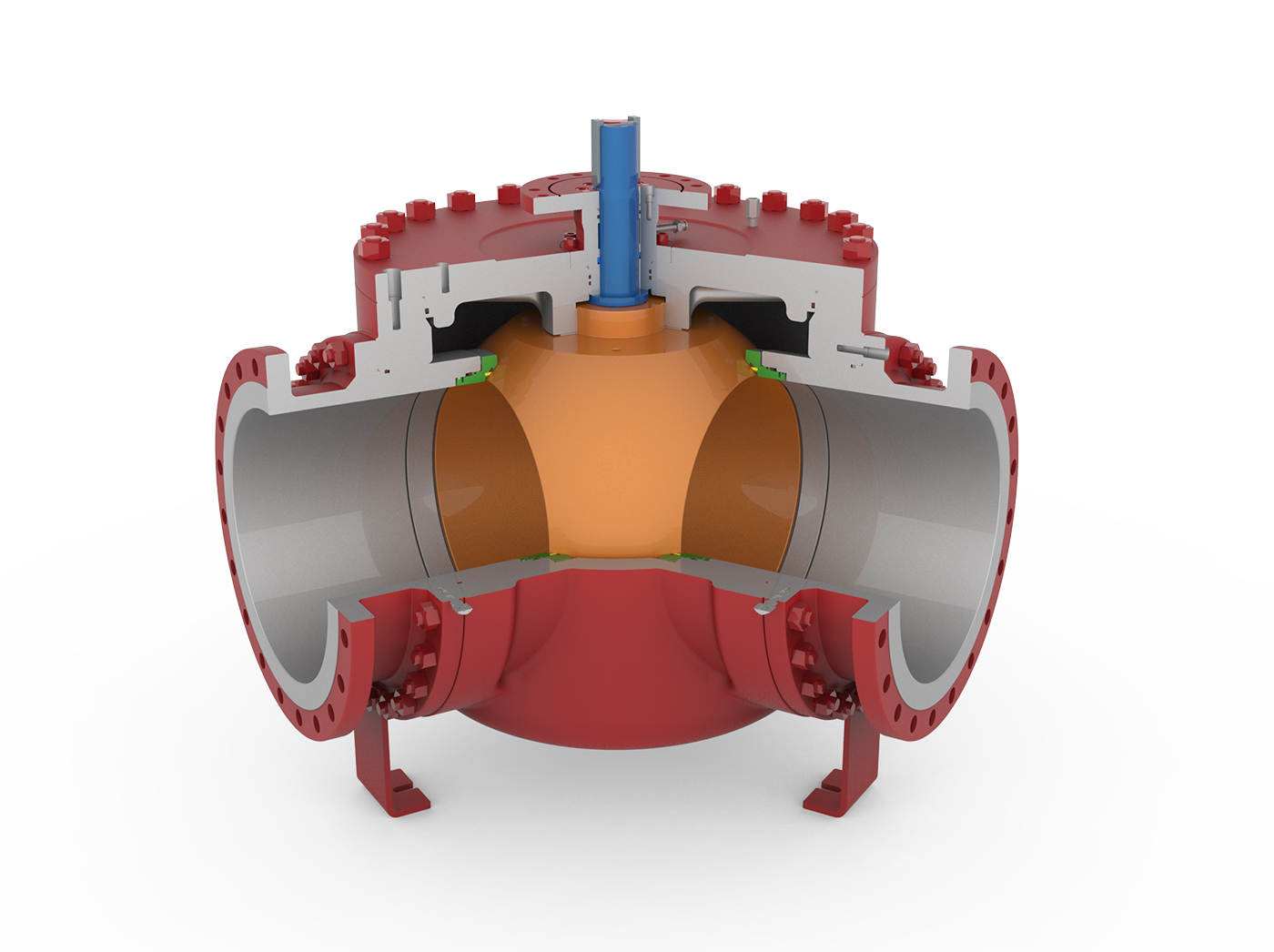

All industrial plants like chemical plants, paper mills, food plants or other industrial plants may need 3-way diverter valves on their piping to handle complicated flow-control processes to save space and make the process more efficient or economical. It takes its basic design structure from the ball valve and operates at an angle of 120 degrees.

3-Way Diverter Valve

Size Range

4" - 42"

Pressure Ratings

ANSI 150 - 1500

End Connections

RF - RTJ - BW

Specifications

| Valve Size | 4″ — 42″ |

| Valve Type | L-Port / T-Port / Y-Port |

| Pressure Class | ANSI 150 / 300 / 600 / 900 / 1500 |

| End Connection | RF / RTJ / BW |

| Operator | Pneumatic Actuator / Electric Actuator |

| Material | Carbon Steel / Stainless Steel / Duplex / Alloy Steel |

| Operating Temperature | Standard |

| Leakage Class | API 598 / ANSI FC70-2 / ISO 5208 |

| Design Standard | ASME B16.34 / ISO 14313 / ISO 17292 |

| Face to Face Standard | According to Manufacturer Specs. |

| End Connection Standard | ASME B16.5 / ASME B16.25/ DIN EN 1092-1 |

| Test Standard | API 598 / ISO 14313 |

| Fire Safe Standard | API 607 / ISO 10497 / API 6FA |

| Certification | EN 10204 3.1 — 3.2 / ISO 15848 Fugitive Emission / 2014-68-EU PED / SIL Capable |

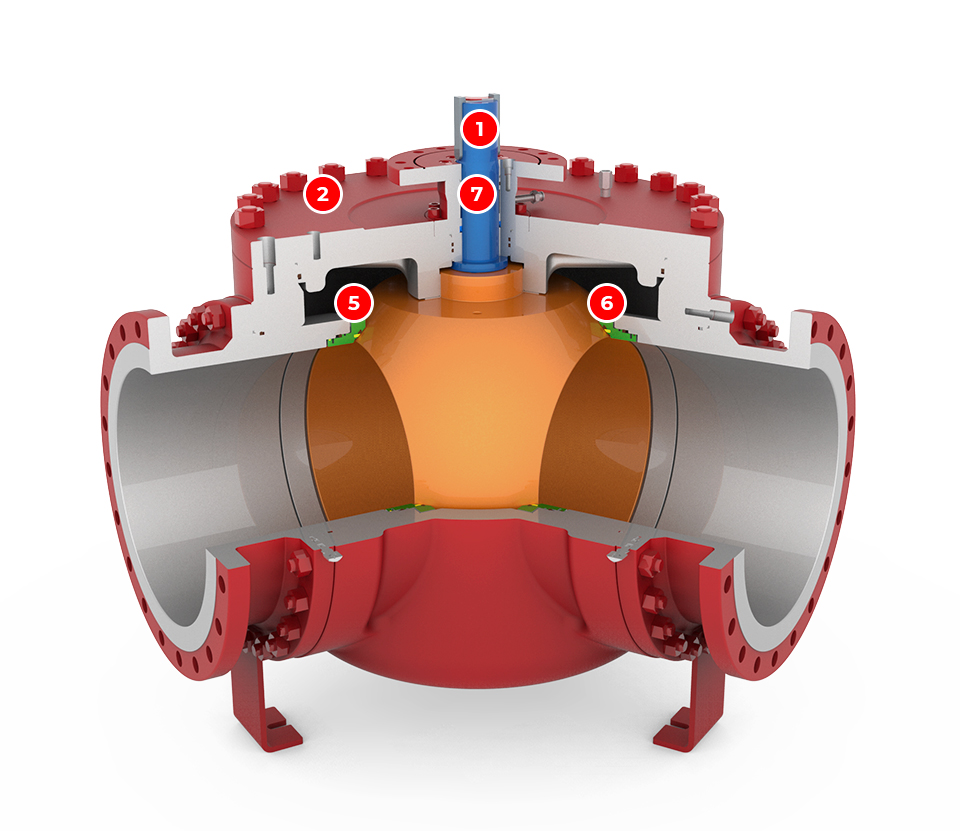

Features

| 1 | Due to low torque values, smaller actuator can be selected. |

| 2 | Fixed lifting lugs on the valve. |

| 3 | Easy maintenance. |

| 4 | Emergency sealing fittings are optional. |

| 5 | Renewable seats. |

| 6 | Available with metal and soft seats. |

| 7 | Blow out proof stem. |

| 8 | Maintenance is possible without removing from the line. |

| 9 | Locking device is optional. |