Pipeline ball valves are used in pipelines on welded jointed spools due to their strong structure and low maintenance needs. They are generally preferred in underground and aboveground applications. Their design provides a lightweight structure and optimum level sealing.

Pipeline Ball Valve

Size Range

2" - 56"

Pressure Ratings

ANSI 150 - 2500

Bore

Full - Reduced Bore

End Connections

RF - BW - SW

Specifications

| Valve Size | 2″ – 56″ |

| Valve Type | Trunnion |

| Body Type | Fully Welded |

| Pressure Class | ANSI 150 / 300 / 600 / 900 / 1500 / 2500 |

| End Connection | RF / BW / SW |

| Bore | Full Bore / Reduced Bore |

| Operator | Lever / Gear / Actuator |

| Material | Carbon Steel |

| Operating Temperature | Standard |

| Leakage Class | API 598 / ANSI FC70-2 / ISO 5208 |

| Design Standard | API 6D / ISO 14313 / ISO 17292 |

| Face to Face Standard | ASME B16.10 |

| End Connection Standard | ASME B16.5 / ASME B16.25 / DIN EN 1092-1 |

| Coating Standard | DIN EN 10290 / DIN 30677 |

| Test Standard | API 6D / API 598 / ISO 14313 |

| Fire Safe Standard | API 607 / ISO 10497 / API 6FA |

| Certification | EN 10204 3.1 – 3.2 / ISO 15848 Fugitive Emission / 2014-68-EU PED / SIL Capable / IP 67 (Gearbox) |

| Isolation Type | DBB / DIB-1 / DIB-2 |

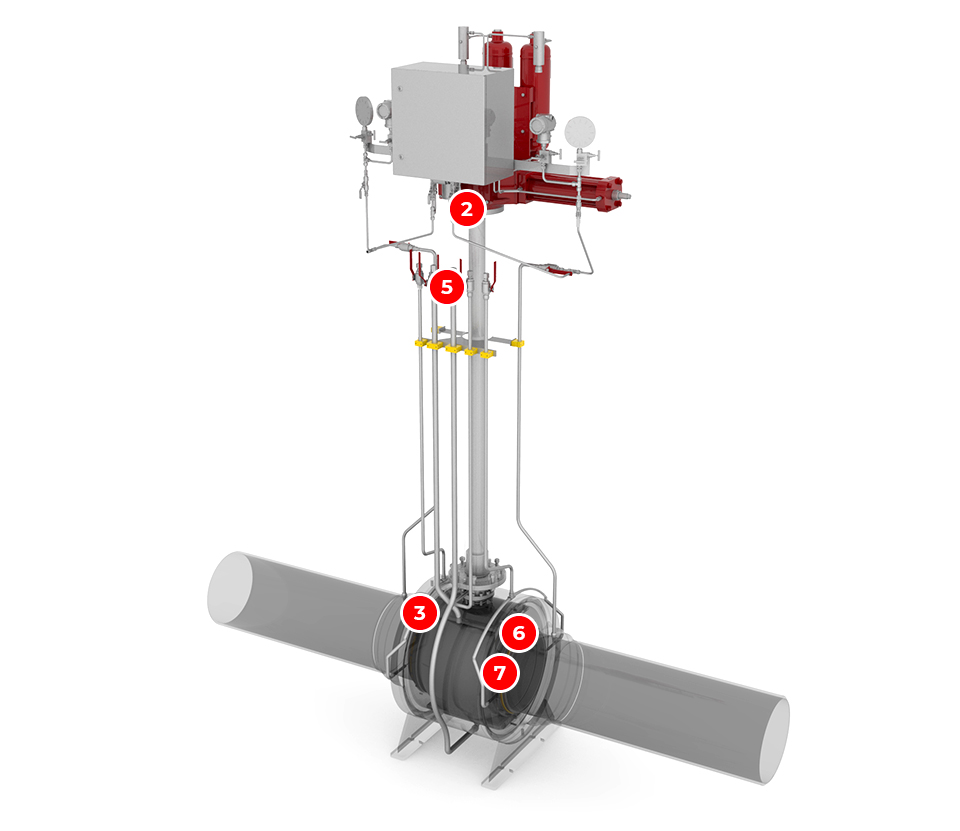

Features

| 1 | Due to low torque values, smaller actuator can be selected. |

| 2 | The actuator selection is automatic. |

| 3 | Fixed lifting lugs on the valve. |

| 4 | Easy maintenance. |

| 5 | Emergency sealing fittings are default. |

| 6 | Renewable seats. |

| 7 | Available with metal and soft seats. |

| 8 | Blow-out-proof stem. |