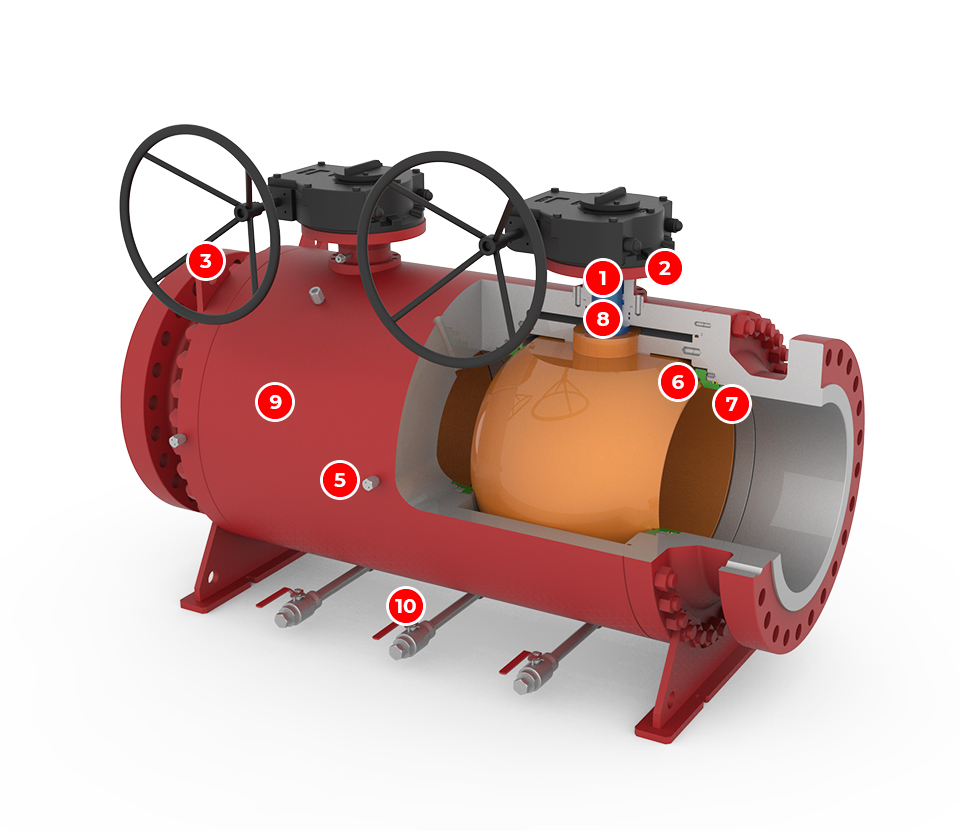

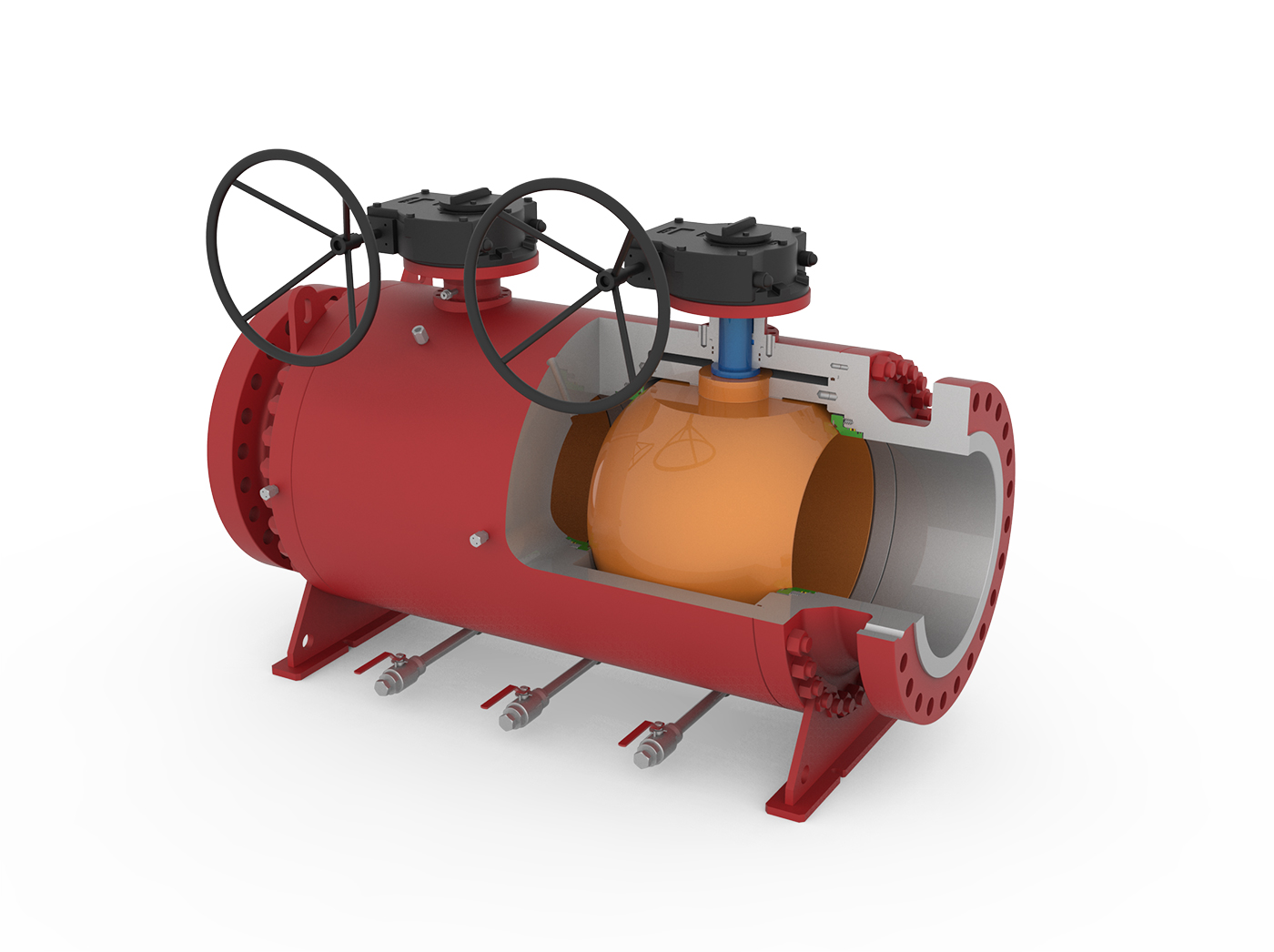

Double ball valves are used in oil & gas industry for their high sealing performance at low pressures and easy on-off operation at high pressure applications. Since the ball is mounted with top and bottom trunnions, torque values are low.

Double ball valves have double block and bleed features which allows the body cavity to drain from both upstream and downstream ends.

Double ball valves are used in critical service conditions. They are preferred because of their high safety.